ChatGPT said: Top ways to work with 10:9 Design Texas for promotional products

All About Screen Printing: A Comprehensive Guide to Its Applications and benefits

Screen printing has a rich history and offers many industries today. Its benefits, including lively shades and durability, make it an attractive selection for bulk manufacturing. Several developers and companies use this method for numerous applications, from fashion to promotional items. Understanding the screen printing procedure is crucial for those seeking to access its capacity. What adheres to is an expedition of its benefits and strategies that could transform innovative undertakings.

The Background of Screen Printing

The advancement of screen printing is a fascinating trip that traces back to old people. The method can be linked to the Chinese, who established a kind of stenciling as early as the Track Dynasty (960-1279 AD) making use of silk and all-natural inks. By the 18th century, screen printing made its way to Europe, where artisans adopted and adapted the method for fabric design.

In the 20th century, screen printing obtained appeal in the United States, especially with the surge of industrial printing and marketing. Artists like Andy Warhol made use of the method, elevating it to an art kind. The introduction of artificial inks and harmonize materials further revolutionized the procedure, making it extra reliable and functional. Today, screen printing is commonly utilized in numerous industries, from fabrics to signage, showcasing its long-lasting relevance and adaptability via the ages.

Benefits of Screen Printing

Screen printing uses numerous advantages that make it a recommended option for several services and musicians. One considerable advantage is its flexibility; it can be related to various products such as plastics, metals, and fabrics, enabling a vast array of applications. In addition, screen printing offers vivid colors and sharp images, making sure high-grade results that stand out.

Applications of Screen Printing

Applications of screen printing are varied, covering different markets and purposes. This flexible method is extensively used in textiles, permitting for vibrant styles on garments, hats, and accessories. In the promotional products field, organizations frequently rely upon screen printing to develop tailored products such as tote, water bottles, and banners, enhancing brand name presence.

In addition, screen printing finds usage in electronic devices, where it is utilized to apply conductive inks on circuit boards. The auto market also gains from this approach, using it printing and sign company near me for ornamental elements and safety labels. The art neighborhood welcomes screen printing for developing minimal version art work and posters, offering artists a means to recreate their job with precision. Ultimately, the packaging market makes use of screen printing for product labeling, ensuring that branding is both attractive and durable. Overall, screen printing's versatility makes it an important device throughout many areas.

The Screen Printing Process

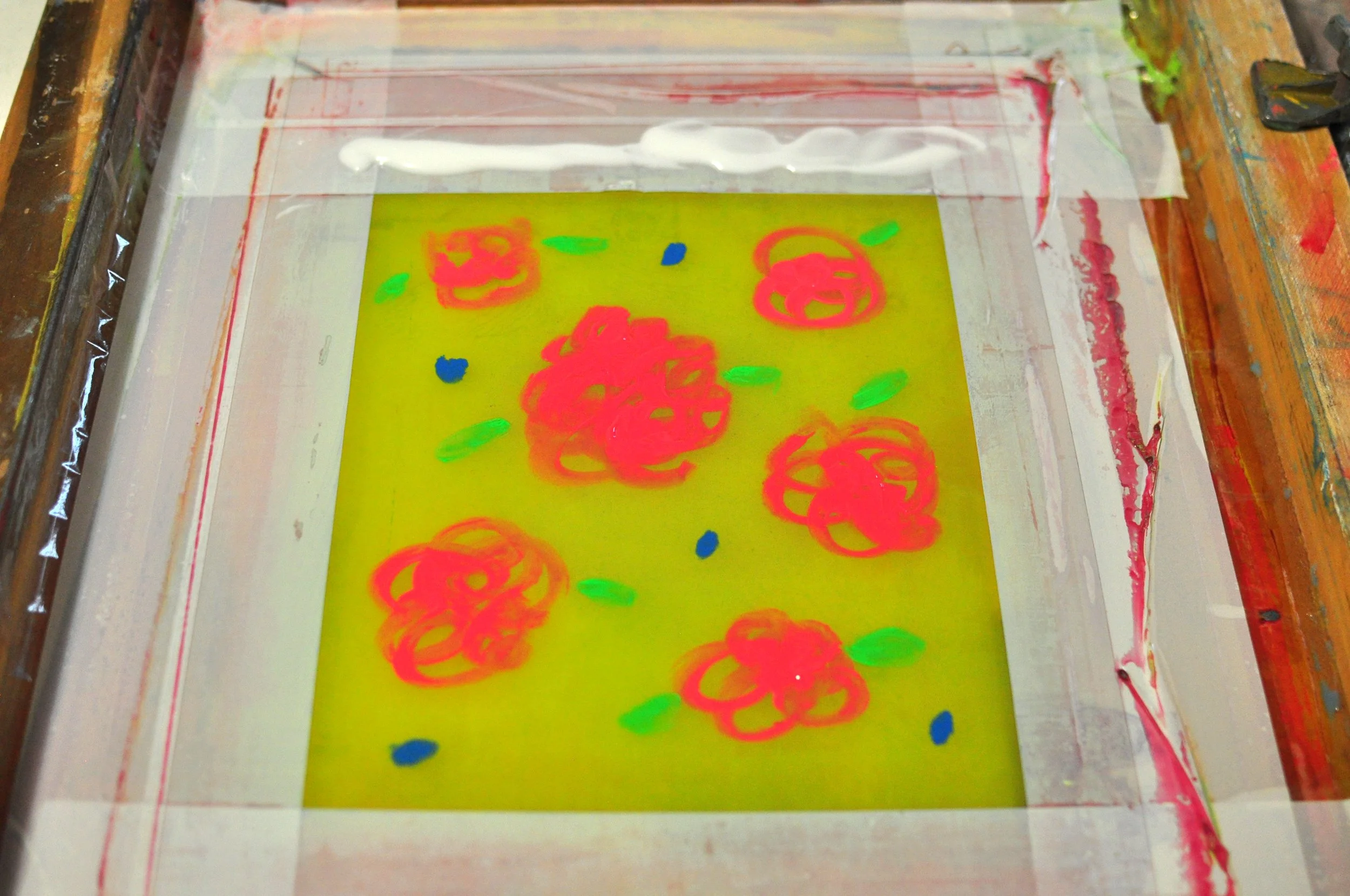

Understanding the screen printing process involves several crucial steps that transform a design into a substantial product. An image is developed and after that transferred onto a display, which is typically made of a great mesh product. A stencil is applied, permitting just certain locations of the screen to pass ink. Next, the screen is positioned over the substratum, whether it be fabric, paper, or another material.

A squeegee is after that used to push ink via the open locations of the pattern onto the substrate. This process can be repeated for numerous shades, needing accurate alignment for each layer. After printing, the item generally undergoes a curing procedure to establish the ink, making certain resilience and vibrancy. This systematic strategy makes screen printing a functional and reliable method for producing high-grade layouts on a variety of products, satisfying both artistic and industrial demands.

Tips for Starting With Screen Printing

Beginning on a screen printing trip can be both tough and interesting for novices. To ensure a smooth introduction, it is important to begin with the right devices. Investing in a standard screen printing kit can give crucial tools without frustrating costs. Newbies should additionally familiarize themselves with the screen printing procedure, including preparing screens, blending inks, and appropriate printing strategies.

Connecting with other screen printers, either online or in neighborhood workshops, can offer assistance and motivation. Lastly, maintaining a clean work space and arranging materials can simplify the printing process, making it extra pleasurable and reliable. With perseverance and practice, newbies can locate success in the globe of screen printing

Frequently Asked Inquiries

What Products Can Be Used for Screen Printing?

Screen printing can use different products, consisting of cotton, paper, polyester, and plastic. In addition, inks such as water-based, plastisol, and discharge are commonly utilized, enabling varied applications throughout fabrics, product packaging, and marketing products.

How Much Time Does Screen Printing Last on Clothes?

Screen printing can last several years on garments, depending on elements like ink high quality, material kind, and treatment guidelines. Correct cleaning and dealing with significantly improve the sturdiness, making certain the layout continues to be vibrant in time.

Can Screen Printing Be Done in the house?

Yes, screen printing can be done in the house. With the right equipment and materials, people can produce custom designs on different garments, permitting individual expression and imagination in their projects without needing specialist solutions.

What Is the Price of Establishing a Display Printing Organization?

Setting up a screen printing organization typically sets you back between $2,000 and $10,000, depending upon equipment top quality, materials, and work space. Additional expenditures include advertising and marketing, utilities, and recurring products, which can substantially influence total investment.

Exactly how Do I Clean Screen Printing Screens?

To cleanse screen printing screens, one need to make use of a solvent to eliminate ink, followed by a pressure washing machine or tube to get rid of deposit. Ultimately, a gentle scrub with a brush ensures that displays continue to be in optimal problem.

In the 20th century, screen printing gained appeal in the United States, particularly with the rise of business printing and advertising and marketing. In addition, screen printing finds usage in electronics, where it is employed to apply conductive inks on circuit boards. Recognizing the screen printing process includes numerous crucial actions that change a style right into a substantial product - 10:9 Design Screen Printing. Screen printing can last numerous years on garments, depending on factors like ink top quality, textile type, and treatment instructions. To clean screen printing screens, one need to use a solvent to remove ink, complied with by a pressure washer or pipe to remove deposit